If you’ve been repairing dental handpieces for a while, you’ve seen how much the industry is evolving. OEMs are tightening control, smart tech is entering the market, sustainability expectations are rising, and supply chains keep changing.

For repair shops, dental laboratories, and wholesalers, staying ahead of these shifts isn’t optional — it’s what keeps you competitive. Access to OEM-compatible dental handpiece parts by brand is becoming just as important as technical skill.

1. OEMs Are Locking Down Repairs

What’s Happening:

Major handpiece manufacturers are increasingly using proprietary components, chips, and specialized assemblies that make third-party repair more challenging.

Why It Matters:

- Restricted access to internal components

- Brand-specific disassembly tools required

- Growing dependency on OEM channels for parts and service

How to Stay Competitive:

- Partner with OEM-compatible parts suppliers that support independent repair channels

- Invest in brand-specific tools and training

- Stay current on manufacturer bulletins and service protocols

Example:

Bien-Air Bora L / MX2 Series — These models highlight the importance of sourcing reliable Star OEM-compatible handpiece parts and brand-specific components as OEM restrictions increase.

2. Eco-Friendly Repairs Are Becoming the New Standard

What’s Happening:

Sustainability is no longer a buzzword—it’s a business standard. Dental repair customers increasingly value partners who reduce waste and extend product life.

What It Means for Repair Shops:

- Demand for recyclable packaging and eco-safe lubricants is growing

- Extended product lifecycles support sustainability goals

- Environmentally conscious practices can win more B2B clients

How to Lead the Charge:

- Use biodegradable packaging and eco-certified chemicals

- Promote reuse programs for housings and non-critical parts

- Incorporate proper handpiece maintenance and lubrication supplies into rebuild workflows

Example:

NSK Ti-Max Z95L — A durable titanium housing allows refurbishment and long-term reuse, reducing waste when paired with proper maintenance practices.

3. Smarter Handpieces Mean Smarter Repairs

What’s Happening:

Smart technology is entering handpieces through embedded electronics, sensors, and digital calibration systems.

What It Means for Technicians:

- Repairs now involve firmware, sensors, and microcontrollers

- Diagnosing issues may require digital calibration tools

- Mechanical precision remains critical

How to Stay Ahead:

- Train technicians to identify electronic and mechanical failures

- Offer performance verification after rebuilds

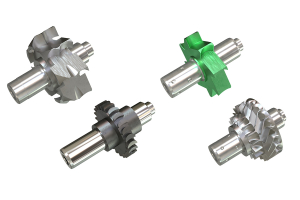

- Use high-quality precision dental handpiece bearings to maintain speed and balance

Example:

W&H Primea Advanced Air — A smart-enabled handpiece that raises the bar for diagnostics and precision component replacement.

4. Supply Chains Are Still Volatile (But Full of Opportunity)

What’s Happening:

Logistics disruptions and regulatory hurdles continue to affect part availability worldwide.

Why It Matters:

- Delayed shipments impact turnaround time

- International sourcing increases compliance requirements

- Reliable inventory builds customer trust

How to Adapt:

- Diversify suppliers across regions

- Maintain stock of high-turn bearings and turbines

- Source parts from experienced wholesale suppliers

Example:

W&H Synea Vision TK-100L — A globally popular model that underscores the importance of dependable parts sourcing.

5. Mobile Repairs and Compliance Are Redefining Workflow

What’s Happening:

Portable tools now allow technicians to perform repairs on-site, while documentation and compliance standards continue to tighten.

What It Means for Your Business:

- Mobile repairs reduce customer downtime

- Serialized part tracking improves accountability

- Proper documentation supports warranty confidence

How to Stay Ready:

- Standardize service documentation

- Use OEM-compatible components with traceability

- Stock commonly replaced parts by brand

Example:

Midwest Stylus Plus / Star Dental 430 SWL — Ideal for mobile repair due to readily available OEM-compatible turbines and bearings.

Wrapping It Up

The dental handpiece repair industry is evolving fast. For wholesale suppliers and repair professionals, success depends on adaptability and access.

- Keeping up with changing repair technologies

- Maintaining access to reliable OEM-compatible parts

- Partnering with suppliers focused on professional repair markets

Handpiece Headquarters supplies OEM-compatible dental handpiece parts exclusively to repair shops, dental laboratories, and wholesalers. Our brand-organized catalog makes it easy to source bearings, turbines, and maintenance products from a single trusted supplier.

Explore our full catalog of dental handpiece parts by brand.

FAQ

Q1: What’s the difference between OEM and OEM-compatible handpiece parts?

OEM parts are supplied directly by the manufacturer. OEM-compatible parts meet or exceed OEM specifications and offer greater flexibility and cost control for professional repair shops.

Q2: How often should a dental handpiece be serviced or rebuilt?

Most high-speed handpieces should be rebuilt every 6–12 months depending on usage, lubrication habits, and operating conditions.

Q3: Do OEM-compatible parts void handpiece warranties?

Once a handpiece is out of its OEM warranty period, using compatible parts is standard industry practice among repair professionals worldwide.